Our organic friction material s are produced in various forms including cloth, composites, fabrics and cellulose paper, and are utilized in transmission, wet brake and industrial motion control systems. Our custom brakes work in various industries, such as farm equipment within the agricultural industry or heavy-duty, armored vehicles in the defense industry. They are designed to withstand the rugged terrain or harsh elements. We can machine, grind and machine precision grooves on all different sizes of roun square, snowman style, and triangles of virtually any size up to three inches thick. Manufacturing facility over 00sq.

Technical collaboration with ASK Technica Japan which is the most reputed friction material OE manufacturer. A brake friction material manufacturer that knowingly violates this chapter shall recall the brake friction material and reimburse the brake friction distributor, retailer, or any other purchaser for the material and any applicable shipping and handling charges for returning the material. When a brake pad heats up due to contact with the rotor, it transfers small amounts of its friction material onto the disc, leaving a dull grey coating on it.

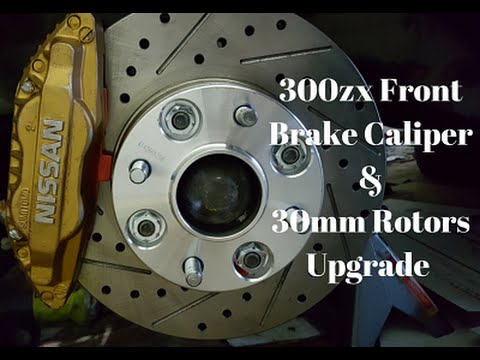

The brake pad and disc (both now having the friction material ), then stick to each other, providing the friction that stops the vehicle.