Visit HowStuffWorks to check out this great disc brake diagram. Most brake diagram s contain the following information: Drawing showing where brake line connections are made and where the lines go to. Line drawing showing the connection of the brake cable from pedal or lever to splitter, and then to wheels. Adjustment points are also shown in most drawings. A gradual slope of the pad material creating uneven thickness on either end of the pad.

One side of the pad set has significantly less unused friction material than the other. A brake repair diagram acts as a repair guide for brake s, providing a clear picture of every individual part of the brake system. A typical brake system diagram shows the location and configuration of the master cylinder, the distribution of the lines, valves, hoses and cables, and the configurations of the discs and rotors.

Other features of a brake system diagram include parking brake elements and vacuum components. Dual-circuit braking system. A typical dual-circuit braking system in which each circuit acts on both front wheels and one rear wheel.

They provide a “hold off” function to allow the rear (drum) brake s to actuate first.

This function is very important in making the system function in the correct sequence in a rear-wheel-drive car. The rear brakes are always actuated first. Designing Your Brake System. There are usually two different holes that the pushrod of the master cylinder can attach to.

If you change from manual to power, you have to change the hole the pushrod attaches to. Common pedal ratios for a manual system are 7:or 8: and 4:or 5:for power systems. Before condemning the air brake system on a trailer, always be sure the air brake system on the towing vehicle is function- ing properly.

The following is based on on the assumption the tractor air brake system is functioning properly.

Brakes need adjusting, lubricating or relining. Tractor protection valve not in “normal” position. Foundation brakes are the most common air- brake systems found in trucks and buses and work the same way as in rail cars. Using the triple-valve principle, air builds up inside the brake pipes or air lines, releasing the brakes.

Diagram of air- brake components. Master cylinder designs vary from one model or manufacturer to another, and many have the front outlet going to the rear brakes and the rear to the front, while others have the opposite arrangement. Many dual outlet master cylinders will have a built in proportion to them. The Air Brake Charging System supplies the compressed air for the braking system as well as other air accessories for the vehicle. The use of the Diagnostic System Check will identify the correct procedure for diagnosing the system and where the procedure is located.

DIAGNOSTIC SYSTEM CHECK - ABS Circuit Description The ABS Diagnostic System Check is an organized approach to identify problems associated with the EBCM. Distortion to the piston seals can be caused as the brake system cools and the fluid returns to the master cylinder. As the fluid returns to the master cylinder reverse force can be applied to the piston seals resulting in distortion and leakage. Replace all affected adjusted cylinders. Install an RCcheck valve.

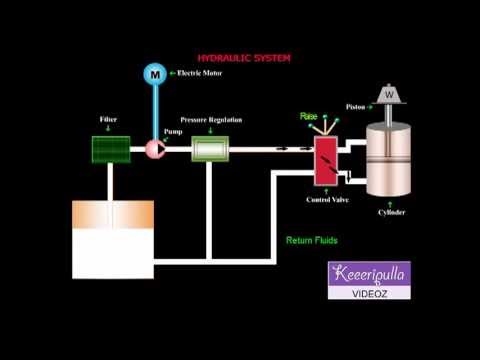

The valve is to adjust the break pressure so you do not have your rear breaks lock up first. You can take away some of the pressure,so the front locks up first. Hydraulic Brake System Master Cylinder Brake Booster.

PBR offers a range of replacement product solutions including hydraulic cylinders and brake calipers including loaded calipers, unloaded calipers and piston housings. Find All Your Brake Parts At NAPA Online. Basic Air Brake System Schematics. These diagrams are provided for basic identification only.

Always consult a professional technician to properly troubleshoot your system. Whether you need a new performance brake line, brake hose en. Parking Brake System - Cable Operated Rear Brakes. Trailer Wiring and Brake Control Wiring.

Technical Drawings and Schematics - Section B. Special light and wiring systems need to be installed on your tow vehicle before you can tow any trailer. The booster reduces the pedal effort required to apply the brakes as compared to a non-power system. The hydraulic booster is comprised of an open center valve and reaction feedback mechanism, a power piston, a and 24-volt backup pump and an integral flow switch.

An example of a hydraulic brake system. In a very simple brake system , with just two cylinders and a disc brake , the cylinders could be connected via tubes, with a piston inside the cylinders. The cylinders and tubes are filled with incompressible oil. The two cylinders have the same volume, but different diameters,.

Without a properly adjusted proportioning valve, the drum brakes will lock up before the discs do which can result in handling problems. Proportioning valves are also useful on 4-wheel disc or 4-wheel drum brake systems, giving you the ability to compensate for tire size differences, weight distribution, etc. The brake systems in this document do not take the special conditions of the trailer such as trailer dimensions, axle types, wheel brake type, tyre type, etc. Based on the brake calculations, it may be possible to determine whether the braking system is suitable for the applications involved.

Brake system warning lights and buzzers are unique to the vehicle manufacturer. The Brake Warning Light and Buzzer Do Not Shut Off flow chart offered in this guide is generic and may not apply to all vehicles. An anti-lock braking system (ABS) is a safety system that allows the wheels on a motor vehicle to continue interacting with the road surface as directed by driver inputs while braking, thus preventing the wheels from locking up and avoid skidding.

An ABS generally offers improved vehicle control. The study of this manual, together with. They transfer fluid pressure to the friction material that stops us. The more pistons we have in a disc brake, the better.

NOTE: In systems where a residual check valve is used the pressure will not return to p. Adding disc brakes or power brakes really improves the performance. Rear disc brakes , Power brake boosters, master cylinders, drop spindle kits, disc brake conversion kits, disc brake brackets, brake line kits, brake cables and more.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.