A gearbox contains a set of gears that engage at an angle in order to change the axis in which one or more output shafts rotate, such as with a right angle gearbox. A speed reducer contains a set of gears that change the speed of the output shaft relative to the input shaft. Rugged cast iron housings, Integral Worm and Shaft, Large single row ball bearings, Gorged bronze worm gears, Heavy-Duty tapered roller bearings,. Whether you need precision or power, we offer solutions for nearly every application and industry. Also known as gearboxes and gear drives, they lower the speed of rotation of the input shaft by a certain ratio and increase the power transmitted to the output shaft by the same ratio.

A gear reducer with straight teeth, for example, is typically only employed in a low-speed application, while a gear reducer with helical teeth, which is much stronger and provides much greater efficiency in terms of torque reduction, is much more likely to be purchased for use with a high-speed application. A gear reducer is a gearing assembly that can reduce rotational speed while increasing torque in a mechanical system, or increase speed while reducing torque (in which case it is called a multiplier). A worm gear reducer is one type of reduction gear box which consists of a worm pinion input, an output worm gear , and features a right angle output orientation. This type of reduction gear box is generally used to take a rated motor speed and produce a low speed output with higher torque value based on the reduction ratio.

A gear reducer is a mechanism by which the energy output of a high-speed motor or engine is redirected to turn another mechanical component at a lower rotational speed and at a higher torque. The purpose of the speed reducer is to reduce the rpm that is transmitted between these two end points. Speed reducers take the torque created by the motor (the input) and multiply it.

If the reducer operates with an insufficient amount of oil, premature gear or bearing failure can occur due to oil starvation. When purchasing a right angle worm gear reducer from TGM, you can select from the TGM product line or from one of the industry standard right angle gear reducers.

GEAR REDUCERS , Without Driving Unit. There are 8in this category Update: We. IronHorse cast iron worm gearboxes (worm gear speed reducers ) are mechanical power transmission drive components that can drive a load at a reduced fixed ratio of the motor speed. The output torque is also increased by the same ratio, while the horsepower remains the same (less efficiency losses).

We carry worm gear reducer products in double reduction, single reduction and worm-helical types for versatile functionality, sourced from industry-best manufacturers. Used gear reducers , gearboxes, gear sets and casings for process industries worldwide. Industrial gear reducers and gearboxes of all sizes and condition are available. Select from all of our available gear reducer ratio, shaft and mounting options to fit your needs and budget.

Literature Dodge Torque-Arm. Motorized Torque Arm, MTA. Gear Reducer , Parallel Shaft, 1. Winsmith gearing products are extensively used in medical and health applications. Our products provide high precision, reduced backlash, low noise performance. Pharmaceutical and sanitary applications demand the benefits of our stainless steel speed reducers.

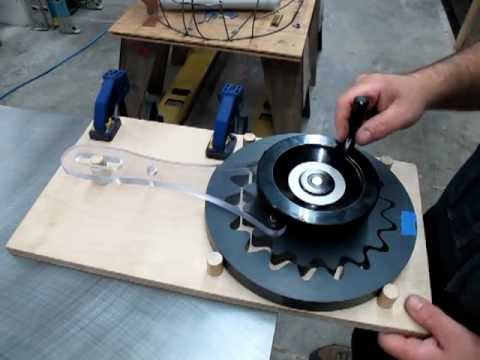

Single stage gear reducer A transmission is a machine in a power transmission system, which provides controlled application of the power. Often the term transmission refers simply to the gearbox that uses gears and gear trains to provide speed and torque conversions from a rotating power source to another device. From design, styling, testing to production service support. Professional gear reducers Supplier.

GAM also has one of the largest selections of precision gear reducers in the world. Worm gear reducers are available in direct or indirect drive, direct drive models are 56C or 145TC flange mount with either right, left or dual output shafts or a hollow bore output. The indirect drive models are shaft input-shaft output boxes for use with sprocket or pulley drive systems. The following is a basic explanation of how gearbox reduction works, along with mathematically-based description of its function. Replacement parts for Dodge gear reducers include seal kits for input and output seals, and bolt-on parts.

Installation parts available for Dodge gear reducers , such as backstop assemblies and motor mounts. The first choice for many of today’s industries, the Master XL offers consistently reliable operation – built for performance and ease-of maintenance. Available in right-angle, parallel and combination outputs, this durable gear reducer is produced in our Columbus, IN, facility with most ratings available to ship within hours.

A planetary reduction drive is a small scale version using ball bearings in an epicyclic arrangement instead of toothed gears. Reduction drives are used in engines of all kinds to increase the amount of torque per revolution of a shaft: the gearbox of any car is a ubiquitous example of a reduction drive. Worm gear speed reducers are comprised of a screw (the worm) that drives a wheel (helical gear ) or single enveloping wheel and are used in mechanical applications ranging from conveyors to exercise devices to robots. The combination of radial load due to torque and tension must be considered when selecting a gear drive.

When connecting a speed reducer with a coupling, and to a lesser extent, line shafts and u. By taking special precautions, problems such as seal leakage and reducer failure due to lack of lubrication, improper lubrication quantity, or contamination can be avoided. Any “B” size reducer bracket may be used with any “B” size reducer , and any “C” size reducer bracket may be used with any “C” size reducer. Shows adjustment range of input (high speed) shaft, allowing the gear reducer to be matched to various drivers.

Below is a list of gear reducer products TECO-Westinghouse is now pleased to offer. For further information, please contact us at 1-800-USE-TECO. Whether custom or off the shelf, we have a solution to meet your application needs. Groschopp’s worm gear reducers are designed with a hollow bore and allow for a corner turn with optional dual output.

The reducers come in ratios ranging from 5:to 100: with non-back-drivable ratios 30:and higher. Small to miniature sized commercial quality worm gear speed reducers are also offered in multiple ratios. Servo Reducers ATLANTA Drive Systems, Inc.

The five levels of precision available allows a machine designer to select the required reducer precision to meet their needs and their budget. Worm gearing is a class of gear reducers that utilizes right angle, non-intersecting shafts. Gearboxes are used for speed reduction and torque multiplication.

This style of reducer provides smooth and quiet operation and allows for the possibility of large speed reductions.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.